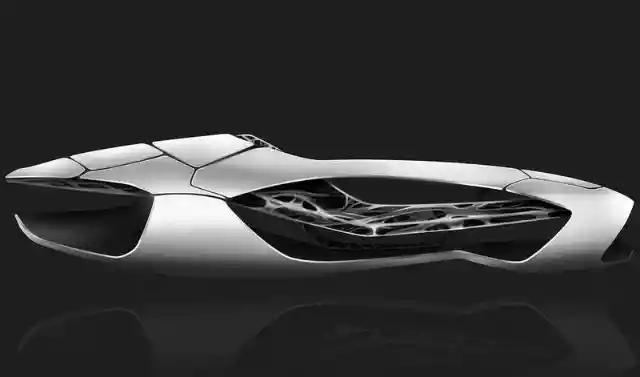

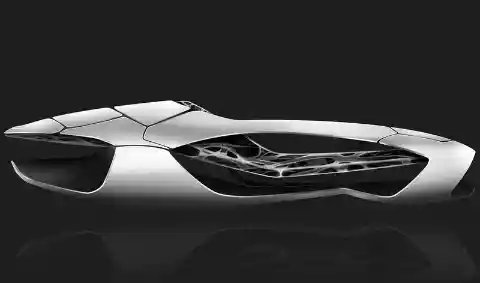

With innovations in the field of 3D printing comes the ability to make a car body that is both economical, fast to produce and more detailed than ever before. EDAF has now revealed its latest 3D-printed car body inspired by the natural design of a turtle shell.

The EDG Genesis is a clear indication of the future for the car building industry in the light of new opportunities offered by 3D-printing.

EDAG is the world number one engineering consultancy for the automotive sector and 3D-printing is set to become a game-changer when it comes to vehicle body design.

The current process requires that car panels are made from metal, composite or fiberglass and must be molded, cut, punched and tooled to make the desired shape. With 3D-printing this is all but eliminated with the ability to make precision parts and parts at the push of a button.

The Genesis, with its turtle-shell inspired body, has been created by robots by laying down each layer of thermoplastic carbon fiber individually. The result is a car body that is strong, flexible and light.

The company produced a 3D printed scale model of the car to show to the industry and provided details on how 3-D printing could dramatically cut down on material waste.

At present Genesis represents a concept for the automotive industry but it demonstrates the capability for change in the sector that 3D-printing can bring. There already exists a 3D-printed car that is almost ready for production.

The Urbee 2, a 3-wheel design, is incredibly light and because of the aerodynamic nature of the body can achieve a fuel efficiency of 290 miles/gallon of fuel.